INDUSTRIAL DESIGN AND OPERATING CHARACTERISTICS

It appears to be little realized by those who prate about human liberty that social freedom of action is to a much greater extent determined by the industrial system in which the individual finds himself than by all the legalistic restrictions combined. The freedom of action of a pioneer was determined principally by his available mode of travel, which was chiefly afoot, by rowboat, horseback, or by animal drawn vehicles. His freedom of communication was similarly circumscribed. His activities in general were accordingly restricted to a relatively small area and to a moderately narrow variety. These restrictions were technological rather than legal. The pioneer could only travel a limited number of miles per day, not because there was a law against traveling more than that, but because the technological factors under which he operated did not allow it.

It is seldom appreciated to what extent these same technological factors determine the activities of human beings at the present time. In New York City, for example, thousands of people cross the Hudson

River daily at 125th Street, and almost no one crosses the river at 116th Street. There is no law requiring the individual to cross the river at 125th Street and forbidding him to cross it at 116th Street. It merely happens that there is a ferry at the former place which operates continuously, and none at the latter. It is possible to get across the river at 116th Street, but under the existing technological controls the great majority of the members of the human species find the passageway at 125th Street the more convenient.

This gives us a clue to the most fundamental social control technique that exists. No other single item exerts more than a small percentage of the influence exerted by the immediate physical environment upon the activities of human beings. Leave the physical environment unaltered, or the industrial rates of operation unchanged, and any effort to alter the fundamental modes of behavior of human beings is doomed largely to failure; alter the immediate physical environment of human beings, and their modes of behavior change automatically. The human animal accepts his physical environment almost without question. He rarely decides to do a particular thing, and then finds himself obstructed by physical barriers. Instead, he first determines the barriers and then directs his activities into those paths where insurmountable barriers do not exist. It is these considerations that render the matter of technological design and operation of equipment of the most fundamental significance. There are standards of design and operation that are wasteful of resources and injurious to the public health. There are other standards of design and operation that are conducive to the general social well-being and lacking in the socially objectionable elements.

In an earlier lesson we laid down the social end-products that will inevitably result from technological operation of the social mechanism. Among these end-products were: a high standard of public health, a minimum of unnecessary drudgery, a high physical standard of living, and a minimum wastage of non-replaceable natural resources.

A high standard of health will result if all human beings are properly fed, clothed, housed, and have all their other biological needs adequately cared for. A minimum of drudgery will be achieved with all routine tasks eliminated or performed as automatically as possible. Natural resources will be utilized with a minimum of wastage if all industrial processes have the highest physical efficiency, and all products will give the greatest amount of service per unit of physical cost.

It will be recognized that it is precisely these criteria that are implicit in a control of industrial operation based upon a minimum degradation of physical energy, as contrasted with our present Price System criterion of industrial control based upon a maximum of profit.

It is into these two fundamentally opposed control techniques that all the thousand and one present day paradoxes are resolved. Social end products are a dependent function of the industrial mode of operation. The criterion determining the mode of operation happens at the present time to be a maximum of profit under a Price System control technique. Granted the continuance of the latter, all gestures at altering the former are futile.

It is our purpose now to review several of our major industrial fields, and to point out the change in design and operating characteristics that would be instituted under the criterion of a minimum of energy cost per unit of use or service produced. Load Factor

Load Factor. One of the first things to be considered in this connection is the matter of operating load factors. A load factor of any piece of productive equipment may be defined as the ratio of its actual output over a given time period to the output that would have resulted in the same time period had the equipment been operated at full load throughout the time. If an engine, for instance, which develops 100 h.p., operates at full load for 24 hours it will produce 2400 h.p. hours of work. Suppose, however, that the engine is operated only intermittently during that time and actually produces but 600 h.p. hours of work in 24 hours. The load factor for that period would then be 600/2400, or 25 percent. The load factor would have been zero had the engine not operated at all or 100 percent had it operated at full load throughout.

There is a fundamental relationship among production, operating load factors, and the capacity of productive equipment. A load factor of 10 percent merely means that the equipment is producing one-tenth of its productive capacity. Now if this same productive capacity were maintained, and the load factor raised to 50 percent, production with the same equipment would be five times as great as with a load factor of 10 percent. If the load factor were 100 percent, the production would be 10 times as great.

If we consider the converse aspect of the same thing, suppose that there is no need of increasing the production of a given kind of product. In this case let us suppose that the load factor is 10 percent, and that load factor is again raised to 50 percent. If production is not increased, we can only achieve this result by junking four-fifths of the plants engaged in that particular kind of production.

Hence it follows that a high load factor, no matter whether used for increasing production or for reducing the amount of plant required for a given production, results always in a diminution in the amount of productive equipment per unit produced, and results correspondingly in a reduction of the energy cost per unit produced.

Quality of Product. Still another factor of comparable importance to that of the operating load factor is the quality of the product. All products are produced for the purpose of rendering some sort of use or service. The total energy cost of this use or service is the energy cost of producing and maintaining the product.

Take an automobile tire for example. The use of the automobile tire is the delivery of so many miles of service. The energy cost of this service per 1,000 miles is the energy cost of manufacturing an automobile tire divided by the number of 1,000 miles of service it renders. Now, suppose that the energy cost of making an automobile tire that will give 20,000 miles of service is some arbitrary figure, say 100. The cost per 1,000 miles would be 5. Consider another automobile tire which will deliver 30,000 miles of service, but costs 120 to produce. The cost per 1,000 miles of service of this latter tire is only 4. Hence it is a better tire than the former because its cost per 1,000 miles of service is less. Suppose, however, that it were possible to make a tire that would last 100,000 miles, but that the cost of producing this tire were 600. Then the cost per 1,000 miles would be 6. This tire, therefore, though longer lived, is actually a more costly tire than either of the other two because the cost per 1,000 miles of service is greater.

It is always possible to find an optimum quality of product for which the cost per unit of use or service is a minimum, and it is this quality which, according to our energy criterion, is the best. Products either longer lived or shorter lived can be built, but they have the disadvantage that the service which they render is more costly than that rendered by the product of optimum quality.

It is interesting to apply these two criteria, the load factor, and the quality of product, to present day industrial operations. Probably the highest load factor of any of our industrial equipment is that of the central power stations. It is only rarely in heavy industrial districts that the load factors of the central power stations are greater than 40 percent. Much more commonly the figure is somewhere around 30 percent. Another of our more continuously operated sets of equipment is the telephone. The busiest lines in the telephone system are the ‘long haul’, long-distance trunk lines, that is, lines such as those from New York to Chicago, and comparable or greater distances. The load factor on these lines for a complete two way conversation is only four hours of operation out of each 24, or a load factor of 162/3 percent. In our less continuously operated equipment, such as factories of all denominations, mines and agricultural equipment, production is intermittent, and the load factor of the equipment is even lower. Few agricultural implements are in use more than a few weeks per year for 8 or 10 hours per day. Few factories run 24 hours per day except for brief rush periods. Most of the remainder of the time they are on one eight-hour shift for a limited number of days per week or else completely shut down.

In the field of automotive transportation, the service rendered is passenger miles of transportation. The average passenger capacity of automobiles is about 5. The average number of passengers carried is considerably less than this. The average time of operation per automobile is approximately one hour out of each twenty-four, giving an operation load factor of only 4 or 5 percent, or a passenger mile load factor of probably not more than half of this amount. If the operating load factor of automobiles could be, stepped up to 50 percent on a 24-hour per day basis, the passenger miles would be ten times that of the present for the same number of automobiles, or else there would be required only a fraction as many cars as we now have.

Considering the quality of products the results are equally bad. Consider razor blades. Suppose that 30 million people shave once per day with safety razor blades and suppose that these blades give three shaves each. This would require a razor blade production of ten million blades per day, which is the right order of magnitude for the United States. Thus, our razor blade factories may be thought of as producing shaves at the rate of 30 million per day at current load factors. Now suppose that we introduce the energy criterion requiring that razor blades be manufactured on the basis of a minimum energy cost per shave. Then the blades, instead of lasting three days, would be more likely to last three years or longer. Suppose they lasted three years. What effect would this have upon our productive capacity in shaves? Technically it is just as easy to manufacture a good blade as a poor one. Thus, the productive capacity at the current load factor would be ten million good blades instead of ten million poor ones per day. But ten million good blades at a life of three years each are equivalent to 1,095,000,000 shaves per day, instead of the 30 million now produced by the same equipment. Since the number of shaves per day is not likely to be materially increased, with the longer lived blade what would happen would be a junking of approximately 99 percent of the present razor factories, thereby eliminating enormous wastage of natural resources.

Low load factors arise from various causes under Price System control. Perhaps the chief cause of low-load factors is the uncertainty of future demand. The individual plant, as we have noted, runs or shuts down in accordance with the orders for goods which it receives. The total purchasing power is sufficient to buy only a small fraction of the goods that would be produced were the existing plant operated wide open. Consequently, the existing plant spends the greater part of its time being shut down or else idling at only a small fraction of full load. This defect is inherent in the Price System and is a direct consequence of the use of money itself.

The Calendar. Another prevailing cause of poor load factors is the calendar. With our present calendar, practically everybody works on the same days, and is off on the same days. This introduces traffic jams and small periods of peak loads on our transportation system, and on our places of recreation, as well as on the industrial equipment. In order to improve the load factor on traffic and on the amusement places, it is necessary for these peaks to be eliminated so that the traffic on one day is the same as that on any other, and for the traffic in any hour of the day to be so adjusted that no extreme peak loads occur.

The technological control that we have postulated removes the element of over-building in productive equipment. A revision of the calendar smooths out the most offensive of the remaining irregularities. The day and the year are major astronomical periods, the significance of which cannot be ignored. The week and the month have no such significance. It is true the month is nominally the period of the moon. Actually, however, our months vary in length from 28 to 31 days, with an average length of 30 and a fraction day. The time elapsed from new moon to new moon is 29 and a fraction of days, so that the phases of the moon shift about a third of a month in the course of one year. So little cognizance is now taken of the moon’s period that the greater part of the population, if asked at any particular time to give the phase of the moon, would have to look it up in an almanac. Consequently, the only astronomical periods that need be considered are those of the day and the year.

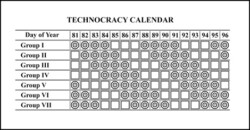

Technocracy’s calendar is, accordingly, based on the day and the year. The year consists of 365.2422 mean solar days. The Technocracy calendar, therefore, would consist in numbering these days consecutively, starting on the vernal equinox from 1 to 364 days, plus 1 zero day (2 zero days leap years). The work period would run for four consecutive days for each individual, followed by three days off. Not taking into consideration the vacation period, every day is a day off for three-sevenths of the working population—all adults between the ages of 25 and 45.

In Figure 9 this is shown diagrammatically for 16 consecutive days chosen arbitrarily during the year. The working population is divided into seven groups, each of which has a different sequence of working days and of days off. The working days of each group are indicated by the circular spaces and the days off by the blank squares. On a basis of 660 annual work-hours and 4-hour daily shifts we arrive at 165 working days, or 41 as the nearest whole number of periods of working days and days off—a total of 287 days. There remain, then, 78 succeeding days as a yearly vacation period for each individual.

Within each group there will be different shifts, the number of shifts depending upon the number of hours worked per day by each individual. If, for instance, the working day were 8 hours, there would be three 8-hour shifts. If the working day were 6 hours, there would be 4 shifts of 6 hours each, and if the working day were 4 hours, there would be 6 shifts of 4 hours each. There will be a transitional period involving large scale reconstruction during which a longer working day of six or possibly eight hours will be retained. Once this period is over, however, there is little doubt but that the working day can be cut to 4 hours.

Figure 9

Numerous questions immediately arise regarding what could be done if two people, husband and wife, for instance, belonged to separate groups, and had their days off on separate days. This need cause no apprehension, because it is a mere administrative detail to transfer a person from one group to another, and since the circumstances under which each group works are identical, there will be in general just as many people wishing to be transferred from Group II to Group I as from Group I to Group II, so that such transfers automatically balance in the end.

In the matter of shifts, however, this is not quite the case, so that in order to make them equal it will probably be found necessary to rotate each individual in such a manner that he works an equal amount of time on each shift during the course of the year.

The effect of this calendar on the load factors of the industrial mechanism would be tremendous. It means that almost the same amount of activity would be going on every hour of the 24. The traffic would be about the same every day and every hour of the day. Each day would be a working day for four-sevenths of the working population, and a day off for the remaining three-sevenths. Consequently, centers of recreation would not be deserted, as they now are, during weekdays, and then jammed beyond capacity the remainder of the time. Instead, ample recreation facilities could be provided so that at no time would the playgrounds, swimming beaches, parks, theaters, or other places of recreation be overcrowded.

Consider also what this means to the central power system. In this case there is a daily cycle of lightness and darkness which is unavoidable. This results in a big load being thrown on the power plants at night due to the necessity of lighting. A large part of this load, of course, goes off during the day. If lighting were the only function of a central power system, such oscillation would remain. However, a large part of the function of a central power system is to provide the motive power for industrial equipment. Certain industrial equipment may be intermittent in its operation, slow freight haulage for example. Now if these intermittent industrial operations are so arranged that they go into operation only during the off-peak load of the power plant, this will enable the maintenance of the load of the power plant at almost 100 percent.

Transportation. Consider transportation under such a mode of control. Transportation falls naturally into two major classes, passenger and freight. Passenger transportation requires, in general, speed, safety and comfort. Freight transportation may be either fast or slow, depending on the nature of the goods being transported. For passenger transportation the principal modes of conveyance are rail, water, highway, or air. For freight transportation there may be added to the above modes of conveyance a fifth, pipeline, and perhaps a sixth, wire. The transmission of energy over a high tension power line and the shipment of coal by freight car are both different aspects of the same thing, namely, the transportation of energy.

In freight transportation, as in all other fields, one of the great problems that would have to be solved is that of which mode of transportation involves the least energy cost per ton-mile. Take the shipment of coal, for instance. Is it more economical of energy to ship the energy contained in coal by freight car, or to hydrogenate the coal and transfer it by pipeline, or to build the power plants near the coal mines and ship the energy by high tension transmission lines?

There is another major problem in freight handling, and that is the matter of freight classification and individual consignments. At the present time all freight is shipped to individual consignees, with the great bulk of it in small lots. Most of this would be eliminated. The supplies for a city, for instance, would all be shipped in bulk quantities to the warehouses of the Distribution Sequence, all goods of a single kind going together. The freight handling terminals and the design of the cars themselves could be made such that the loading and unloading of freight could be handled with the greatest dispatch by automatic methods. From these major freight terminals, goods would be moved locally to the various centers of distribution, from which they would be distributed to the population of the immediate vicinity.

In the matter of passenger transportation, the same criteria would be used in the design and operation of passenger equipment as elsewhere. Trains involving the least energy cost per passenger mile would be operated. It goes without saying that such trains would be the lightest, the most streamlined and the most efficiently powered that could be built. Whether Diesel-electric power units mounted on the trains themselves, or whether power derived from stationary central power plants will prove to be the most efficient, and hence the preferred mode of propulsion, is still to be determined.

Since by far the greater number of passenger miles of transportation are delivered by automobiles operating on public highways, particular significance attaches to this mode of transportation. To appreciate the importance of automobiles in our national economy, one needs only to consider that in, 1923 passenger automobiles in the United States had an installed horsepower capacity of approximately 453,000,000 h.p. All the other prime movers combined at that time were only 231,000,000 h.p., giving a grand total of 684,000,000 h.p. of prime movers. By 1929 this grand total reached over 1,000,000,000 of installed horsepower, with automobiles occupying as great if not greater proportion as in 1923. In 1923 the h.p. capacity of passenger automobiles was 66 percent of the total of all the prime movers in the country. In that year, the number of passenger automobiles was about 13,000,000. By 1929 this had reached 23,000,000, with the horsepower per automobile increasing simultaneously.

Now, getting back to load factors, we have already remarked that the average load factor of all automobiles is only about 5 percent. This means then that at the present we have approximately 800,000,000 installed horsepower in passenger automobiles alone which are operating only about 5 percent of the time. Or it means that if we could step this load factor up to 50 percent, or 10 times what it now is, we could obtain the same number of passenger miles with one-tenth of the automobiles now in operation.

There is a corresponding problem involved in the design and servicing of automotive vehicles. Today there are about two dozen separate makes of automobiles being built in the United States. This means that as many different factories have to operate, and that a corresponding number of complete systems of garages and service stations must be maintained.

The factors that are uppermost in present day automotive design are those of flashy appearance and other superficialities that make for ready sales; while it is as carefully seen to that the wearing qualities are kept low enough to insure a quick turnover because of the short life of the product. To this end all sorts of fake devices are used, the latest of which is fake streamlining.

In the matter of fuel efficiency, by far the most efficient type of internal combustion engine is the Diesel, which operates on fuel oil or distillate. Although automobile and airplane Diesels have long since been proven to be entirely practicable, they have for a number of years past been carefully withheld from use in automobiles. There is, however, a limit to the extent to which so fundamental an advance as Diesel engines can be withheld, and now, at last, the dam has broken. In trucks, tractors and buses Diesels have been coming in at a very rapid and accelerating rate during the past two years, and now one manufacturer announces a Diesel motor as an optional choice in an automobile. While it is true that a part of the phenomenally low cost of Diesel operation at present is the low cost of fuel oil, and that as the demand for this increases, the monetary price will rise, the fact still remains, however, that Diesels do the same work for fewer gallons of fuel than any other engines in existence.

Under an energy criterion it follows that all automotive vehicles would be powered with the most efficient prime movers that could be designed—high-speed Diesels, unless and until something better can be devised. The same considerations would apply to all the various trick devices for insuring rapid obsolescence and turnover in vogue today. To care for these and other defects of the function of automotive transportation necessitates a complete revision from the ground up. Consequently, to improve the load factor it will be necessary to put all automobiles under a unified control system whereby they are manufactured, serviced, and superintended by the Automotive Branch of the Transportation Sequence.

This means, in the first place, that there would be only one basic design of automobile. That is, all automobiles that were built would have interchangeable parts, such as motors, wheels, chassis, springs, etc., except insofar as they differed in those elements of design fitting them for different uses. In these minor differences there would be as many different varieties as there were uses, such as two-passenger and five-passenger capacity, light trucks, and similar variations. It goes without saying that, in accordance with our criterion of least energy cost, the cars would be really streamlined, which would require that the engine be placed in the rear, rather than in the front; they would be powered with the most efficient power unit that could be devised.

As regards use of the automobiles, the change of administration would be even more profound. Whereas, at the present time, one buys an expensive automobile, and leaves it parked the greater part of the time in front of his house as evidence of conspicuous consumption, the automobiles that we are speaking of would have to be kept in operation. This would be accomplished by instituting what would resemble a national ‘drive it yourself’ system. The Automotive Branch of Transportation would provide a network of garages at convenient places all over the country from which automobiles could be had at any hour of the night or day. No automobiles would be privately owned. When one wished to use an automobile, he would merely call at the garage, present his driver’s license, and a car of the type needed would be assigned to him. When he was through with the car, he would return it either to the same garage, or to any other garage that happened to be convenient and surrender his Energy Certificates in payment for the cost incurred while he was using it.

The details of this cost accounting for automotive transportation are significant. The individual no longer pays for the upkeep of the car, or for its fueling or servicing. All this is done by the Automotive Branch of the Division of Transportation. In this manner a complete performance and cost record of every automotive vehicle is kept from the time it leaves the factory until the time when it is finally scrapped, and the metal that it contains is returned to the factory for refabrication. In this manner the exact energy cost per car-mile for the automotive transportation of the entire country is known at all times. Similar information is available on the length of life of automobiles and of tires. With such information in the hands of the research staff, it becomes very definite as to which of various designs is the superior or the inferior in terms of physical cost per car-mile.

The total cost of automotive transportation includes, of course, the cost of manufacturing the automobile. If, for instance, the average life of an automobile were 300,000 miles, the total cost for these 300,000 miles would be the cost of manufacturing the automobile plus its total cost of operation and maintenance during its period of service. The average cost per mile, therefore, would be this total cost including the cost of manufacture, divided by the total distance traveled, in this case 300,000 miles.

Where there are millions of automobiles involved the same type of computation is used. In this case the average cost per mile would be the average cost for the millions of cars instead of for only one. This would be the total cost of manufacture, operation, and maintenance of all automobiles of a given kind divided by the total miles of service rendered by these cars. Since automotive costs can best be kept low by maintaining high operating load factors, it becomes necessary that all automobiles be kept in as continuous operation as is practicable. In other words, automobiles when away from the garages should be in operation and not parked ostentatiously in front of somebody’s house. This can be taken care of rather effectively by charging the individual for the use of the automobile on a mileage time basis as follows: (1) if while the automobile is out its operation has been maintained at a rate equal to or greater than the national load factor for all automobiles, charge is made on a mileage basis only; (2) if the load factor of the car while out is not kept equal to the average load factor, the charge is made on the basis of the number of miles that the car would have traveled during that time had it operated at a rate equal to the average national load factor for automobiles.

Suppose, for instance, that the average national load factor for all automobiles were such that each car traveled on the average 240 miles each 24 hours, or an average of 10 miles per hour. Now, if a person had an automobile out and he used it an average of 10 miles or more per hour, he would be charged for mileage only. If, however, he kept the car 24 hours, and only drove it 30 miles, he would be charged for 240 miles, for that is the distance the car should have traveled in 24 hours.

This simple proviso has the dual effect of improving the load factor of all automobiles, and at the same time reducing the average cost per mile, by making the delinquents pay for keeping automobiles out of service.

Communication. The field of communication includes mail, telegraph, telephone, radio, and television. All of these forms of communication plus any others that may be developed are in the domain of the Communication Sequence. Under an energy criterion the same question arises here as elsewhere. Namely, of two equally effective modes of communication which has the least energy cost per unit? The unit in this case is a given number of words transmitted a given distance.

Technically there is no question that all communication of the entire Continent could be conducted by telephone if the energy cost indicates that this is not too expensive. It is equally possible to do the same thing by telegraph. Facsimiles, or photographs so accurate as to be scarcely detectable from the originals, are now being sent by wire as a matter of daily newspaper routine. Whether the energy cost of handling the entire communications by telephone or by telegraph is less than by mail, available data are not sufficient to decide. They indicate, however, that the cost by wire would be at least as small as by mail, if not smaller.

Suppose that the mails be maintained even if at a considerably reduced volume. One of the great technological improvements awaiting introduction into this branch of activity is that of automatic sorting. Few more drudgerous jobs exist at the present than those of the postal clerks who spend year after year poking letters into pigeon-holes. Technically it is possible to devise a mail system whereby a letter will be transmitted from one side of the Continent to the other virtually untouched by human hands. One way whereby this could be done would be by uniform sized envelopes bearing code addresses of black and white spaces, a different combination corresponding to every different mail distribution center. This would permit sorting by photo-electric cells.

In the matter of radio, the same unification of equipment would be effected. Instead of having dozens of different kinds of radio sets, there would only be one kind for each specific purpose. That kind, needless to say, within the physical limitations set, would be the best that could be built. The individual radio set would be a part of the Radio Branch of the Communications Sequence, just as the individual telephone is now a part of the telephone company and not the property of the user.

Agriculture. Just as far-reaching implications are met when one applies the same criteria to agriculture. Agriculture is the nearest to the primary source of energy, the sun, of all our industries. Agriculture is fundamentally a chemical industry wherein matter from the soil and the atmosphere are combined with the help of solar and other energy into various use products. Only now are we beginning to appreciate the latitude of usefulness to which agricultural products can be put. From time immemorial products of the soil have been the source of human food and clothing. But many more products from the soil have been wantonly wasted—wheat straw, corn-cobs, and numerous other products are normally burned or otherwise destroyed.

From a technological point of view, agriculture is still probably our most primitive and backward industry. Land is cultivated in small patches by people whose knowledge is largely of a handicraft type handed down from father to son. Soils are allowed to waste away by erosion or by lack of fertilization; farm implements are used for the most part for only a few weeks per year each, and more often than not left standing exposed to the weather the remainder of the time.

While it is true that agriculture as it is practiced on most of our farms today is largely in a handicraft stage only slightly different from that of the ancients, the same cannot be said of the scientific knowledge of agro biology. Modern agrobiologists look upon plants merely as mechanisms for converting certain inorganic substances—principally phosphates, potash, and nitrogen—known as plant foods into forms useful both as foods and as raw materials for industrial uses.

Soil, as such, is of no importance except as a container of plant foods and as a support for the growing plant. It follows, of course, that any other container for properly proportioned plant foods, used in conjunctions with a suitable support for the growing plant, would constitute an alternative to an agriculture based upon tilling of the soil.

Consider, however, that the soil still be used as the agricultural base. In this case all soils contain an initial amount of usually improperly proportioned plant foods, and will, without other attention than primitive tilling, produce a modicum of various kinds of crops. Since each crop grown extracts a part of the supply of plant food initially present in the soil, it follows that if succeeding crops are produced without a corresponding amount of plant food being added, the soil will gradually be exhausted of its initial supply and become ‘run down’ or worn out. Such a soil can be rejuvenated by merely adding the plant foods in which it has become deficient. Hence it follows that over any long-time period there must be maintained an equilibrium between the plant foods added to the soil and those taken out, if continued producing power without soil exhaustion is to be maintained.

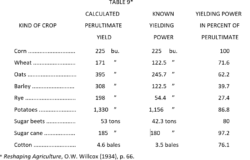

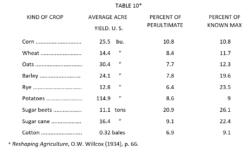

This brings us to the question of yields to be expected per acre. Modern agrobiologists have determined that where soil is utilized as the medium of crop culture, and where crops are grown under ordinary out-of-door conditions, there is a theoretical maximum yield per acre which any crop may be made to approach, but none to exceed. This maximum is determined by the amount of nitrogen that may be extracted from the soil per acre. The maximum of nitrogen extraction that may not be exceeded by any one crop in a given cycle of growth is approximately 320 pounds per acre. In order that 320 pounds of nitrogen be withdrawn it is required that there be present 2,230 pounds of nitrogen per acre. By knowing the amount of nitrogen withdrawn from the soil to produce one bushel of corn, of wheat, or of potatoes, one ton of sugar cane, or one bale of cotton, one has merely to divide this amount into 320 pounds of nitrogen per acre in order to determine the maximum possible yield of the crop considered. These maximum possible, or penultimate yields, together with yields that have already been achieved, are given by O. W. Willcox as follows:

TABLE 9

As compared with the above maxima, Wilcox gives the average crop yields per acre for the United States as follows:

Average yields of crops in the United States compared with the possible maxima:

TABLE 10*

The significance of these facts is that our American agriculture is operating at an extremely low efficiency—less than 10 percent of the theoretical maximum, and only about 15 percent of actual best performance under field conditions. Furthermore, in the light of present technical knowledge in the field of agro biology, it would be no difficulty at all to step this production up to at least 50 percent of the penultimate maximum. Even today almost every year that passes sees new records broken in actual crop yields per acre.

An average agricultural efficiency of 50 percent means that the same agricultural production as at present can be achieved on one-fifth of the land area now in cultivation, with one-fifth or less of the man-hours now required.

An even more fundamental and technological approach to agricultural production is to be found in those cases where the soil is no longer considered necessary as a container for plant food or as a supporter of the growing plant. Such an example is to be found in the case of the process currently in use in California and elsewhere. In this process the plant food is dissolved in water which is contained in a long shallow trough. Above the water, and supported by wire netting, is a bed of excelsior in which the seeds are planted. The roots extend downward to the water. The excelsior and wire netting support the plants. In this manner optimum conditions can be constantly maintained and almost phenomenal production results.

Further technological control of environmental factors and the speeding up of growth rates and shortening the period required to mature a crop are as yet little touched, but offer broad domains for the technologist in agrobiology in the future.

Regardless of whether the agriculture of the future ultimately remains predominantly in the out-of-doors farming stage or comes to resemble an agricultural factory, the fact remains that the application of the technological methods will revolutionize it to where present methods are truly primitive in comparison.

Suppose that out-of-doors agriculture remains predominant. Large scale operations require large tracts of land worked by machinery gigantic in size as compared with any that present day farmers are able to employ. Land-breaking to depths of two to three feet is not at all impracticable with equipment designed for that purpose. Such deep plowing in conjunction with run-off control of the water supply would practically eliminate drought hazards. Proper fertilization and tilling would do the rest. Only the best land and agricultural climates need be utilized because with such yields as could be obtained by those methods little more land than is contained in the state of Illinois would be required for all agricultural produce for the United States.

Needless to say, all present farms and land divisions would be eliminated. Agriculture would be only one division of a vast chemical industry which would convert the raw materials of the land into use products and in turn supply to the land its requirements in fertilizers and plant food. Tracts of probably tens of miles square would be worked as a unit. Equipment would operate 24 hours per day and be rotated in such a manner that each piece of equipment would be in as continual operation as possible throughout the year.

The farm population would live in conveniently situated towns from which they would commute to the fields. They would thus combine the advantages of healthful out-of-doors work with those of urban life with its social and educational facilities.

This would, of course, leave vast domains to be reconverted either to grazing or forest lands. Forests, national parks, and playgrounds could then be instituted on a scale never known since the country was in its virgin state as found by the original pioneers.

Housing. So great is the effect of habit on the human animal that it becomes almost impossible for one to detach himself sufficiently to take an objective view of the subject of housing. Our houses and our buildings and structures generally resemble our clothing in that they attain a certain convention and thereafter we tend to accept them without further question. It never occurs to us to ask whether the prevailing convention is better or worse than other possible styles. The training of our architects is such as to tend to perpetuate this state of affairs. Aside from draftsmanship and a small amount of elementary training in strength of materials and other structural details, our students of architecture spend most of their time studying the architectural details of the ceremonial buildings of the past—temples, cathedrals, palaces, and the like. This accounts for the fact that power plants are seen with Corinthian columns, banks with Gothic windows, and libraries resembling Greek temples.

The problem of designing buildings in accordance with the functions they are to perform seems rarely to have occurred to architects.

The successful architect of today is either one who has developed an architectural firm that receives commissions for designing large and expensive buildings, such as skyscrapers, hospitals, courthouses, and the like, or else an individual practitioner who knows sufficiently well the pecuniary canons of good taste to receive commissions for the design of residences in the expensive residential sections of our cities and their suburbs.

If an architect wishes to be really ‘modern,’ he then proceeds to do something ‘different.’ He designs houses made completely of glass or metal, and hung from a post. The two basic questions that seem never to occur in connection with these endeavors are: ‘What is the building for’? and ‘Would it be practicable to house the inhabitants of an entire continent in such structures’?

This brings us to the technological foundation of the whole subject of housing, namely, what are the buildings for? What do we have to build them with? What does it cost physically to maintain them? And how long will they last?

The physical cost in this field is arrived at in the same manner as in the physical cost in any other field. The physical cost of housing 150,000,000 people is the physical cost of constructing, operating, and maintaining the habitations for 150,000,000 people. The cost per inhabitant per year is the total cost per year divided by the number of inhabitants.

If housing is to be adequate for 150,000,000 people, and at the same time physical cost of housing is to be kept at a minimum, there necessitates a complete revision of design, construction, and maintenance in the whole field of housing. It requires that the construction of houses be kept at a minimum cost, that the life of each house be a maximum, and that the cost of maintaining each house, including heating and lighting, be a minimum. It requires, furthermore, that the materials used be those of which there is an ample supply for the construction and maintenance of approximately 50,000,000 dwellings. This immediately rules out the whole array of ‘modern’ designs of metal houses, where the metal involved is chromium and other similar rare metals, which are indispensable as alloys of steel and other metals for industrial uses.

The requirements of low cost construction would necessitate that the housing be of factory fabricated types, where the individual units can be turned out on a quantity production schedule ready for assembly, just as automobiles are now turned out by automobile factories. There would be a limited number of models, depending upon the type of locality in which they were to be used, their size and the type of climate. Any of these different models, however, could be assembled from the same units—wall units, doors, windows, bathroom, kitchen equipment— as any other model; the difference being that these standard units are merely assembled in different combinations.

Instead of thousands of separate individual architects designing houses, there would be only a few basic designs, and these designs would be made by the best technical brains that could be had for the purpose. The building would be designed for use, for long life, and for minimum cost of construction and maintenance. Incorporated into the design of the house would be the design of the furniture as an integral part. The houses would not only be heated in winter, but cooled in summer, and air-conditioned throughout the year. The lighting would be indirect, and with intensity control for the best physiological effects.

While there is a wide variety of possible materials, the fundamental conditions that must be fulfilled are abundance, low energy cost of fabrication, and high degree of heat proofing and soundproofing qualities, as well as a structural framework rendering it vibration-proof against such impacts as occur in the ordinary activities taking place inside a dwelling. In other words, one should be able to make all the noise he pleased, or do acrobatic flip-flops, in such a house without a person in the next room being able to detect it. The building should be proof against not only the leakage of heat from the inside out, or vice versa, but also completely fireproof.

The method of heating in such a structure also would be radically different from those now employed. It is quite likely that a thermodynamic type of heating, based on essentially the same principle as our present gas flame refrigerators would prove to be the most efficient. In this case, however, when the house is to be heated instead of cooled, the cold end of the mechanism would be placed outside the house —probably buried in the ground—and the warm end placed inside the house. The fuel, instead of being used to heat the house directly as is done now, would merely be used to operate the refrigerating mechanism which would pump heat into the house from the outside. By such a method, theoretical considerations indicate that a house can be heated at only a small fraction of the energy cost of the most efficient of the direct heating methods obtainable.

This method of heating has the additional advantage that by changing only a few valves the system could be made to run backwards, that is, to pump heat from inside to outside of buildings, and thus act as a cooling device during warm weather, which would be analogous to our present refrigerator, only on a larger scale.

Design. The end-products of design are radically different if one lays out the whole scheme of a given function in advance and then works down to the details, from what they would be if one started on the details and worked from them to the more general complex. For example, the steamship Normandie has been able to break world speed records and to exhibit other points of functional excellence merely because these high points of performance were written into the specifications before a single minor detail was ever decided upon. The design of a ship to meet these broader specifications automatically determined that the minor details be of one sort rather than a number of others. The specification that the Normandie was to be the fastest steamship ever built automatically determined the shape of the hull, the power of the engines, and numerous other smaller details.

Suppose the procedure had been in the reverse order. Suppose that some one person decided independently upon the shape of the hull; suppose that a second designed the engines, determining what power and speeds they should have. Let a third design the control apparatus, etc. It is a foregone conclusion that a ship designed in any such manner, if she remained afloat or ran at all, would not break any records.

For any single functional unit, the design specifications for the performance of the whole must be written, and then the details worked out afterwards in such a manner that the performance of the whole will equal the original specifications laid down.

The trouble with design in a social mechanism heretofore has been that either the specifications nor the design has ever gone beyond the stage of minute details. We have designed houses by the thousands, but no one has ever designed a system of housing on a continental scale. We have designed individual boats, automobiles, locomotives, railway cars, and even articulated streamlined trains and individual airplanes, but no one has ever designed a continental system of transportation. Even these latter units are only individual details in the design of a whole operating social mechanism. Even a design that embraced whole functional sequences would be inadequate unless it in turn was guided by the super design of the entire social mechanism.

So far, we have only been suggesting some of the details of the type that would result from such a shift of viewpoint and of administration as would be entailed in a transfer from the present politico-economic Price System mode of social administration over to the functional technological type that we have outlined. In such a change no single detail, big or small, would be left untouched. There would be a whole re-allocation of our industries. Our present centers of trade and commerce, as such, would dwindle into insignificance for the simple reason that trade and commerce would cease to exist. Centers of industry might or might not come to occupy the same places. The entire array of man-made buildings and equipment of the whole North American Continent would have to be junked and replaced by more efficient and better functioning structures and equipment. Along with redistribution of industry would come a redistribution of population. It is not improbable that New York City and other similar localities would be mined for the metal they contain.

New towns and cities would have to be designed as operating units from the ground up, and these designs would again be only details of the super-design for the whole mechanism. There are a number of essential design elements that must be taken into account in the design of a town or a city:

- There must be adequate housing and recreation facilities for the population.

- There must be an adequate distribution system for the supplies that will be consumed by the city, both by the populace individually and by the city itself.

- There must be an adequate system of waste disposal, sewage, garbage, and the like.

- There must be adequate facilities for local traffic, pedestrian, vehicular, etc.

- There must be adequate facilities for local communication.

- There must be a system of water supply, of heat, gas, and electric power.

- There must be trunk connections for traffic, supplies, water, energy, and so on, between the city and the world outside.

- The design must be such as to allow for any probable expansion in the population with a minimum of readjustment.

Standardization. In the field of more general design, standardization of more essential parts will be carried as nearly as possible to perfection. Outside of industrial circles it is little realized what standardization means. In the maintenance of even the present rate of industrial operation, suppose, for example, that every separate manufacturer of electric light sockets produced a different size. If these sizes were as many as a few dozen almost hopeless confusion would result. Suppose likewise that every different state in the union used a different sized railway gauge, as is the case in Australia. This would mean that all trains would have to stop at the state lines and transfer freight and passengers, because a train from Illinois would not be able to run on the Indiana tracks. These examples are taken merely to show the importance of such progress in standardization as has already been made. Few people realize that our present quantity production in automobiles is rendered possible entirely by the standardization of machine parts. Many automobile parts have to fit with an accuracy of one ten-thousandth part of one inch. In order that all such parts in a quantity production flow line turning out thousands of units per day may be mutually interchangeable, it is imperative that all these parts be standardized with that degree of accuracy. Most of the difference in cost between a Rolls-Royce and a Packard is due to the fact that the Packard is produced by standardized quantity production methods, whereas the Rolls-Royce is produced by handicraft methods where every individual bearing is fitted separately and, in general, parts are not mutually interchangeable. If the Packard of today were built by the same hand methods employed in the Rolls-Royce, it would be no whit better than it is now, but it would have to sell for a price comparable to that of the Rolls-Royce, and for the same reasons.

Most of our industrial progress up to the present time has been rendered possible through standardization. The trouble is that standardization has not been carried nearly far enough as yet. There are too many different arbitrary sizes and varieties of what is functionally, the same-commodity. Take a simple product like soap. Chemically there are only a small number of separate basic formulas for soap. The number of brands of soap on the market, however, runs into the thousands.

Not only has the achievement of standardization made possible our quantity production methods, but the lack of standardization has at the same time been in no small part responsible for our low industrial load factors. In many fields, particularly in those of clothing and automobiles, the lack of standardization has been promoted as a highly remunerative racket—the style racket. If styles can be manipulated properly it is possible to increase the consumption of goods by rendering the styles of the old goods obsolete long before the goods themselves are worn out. Thus clothing, which might last two years, is discarded at the end of a single season because it is out of style. Last year’s automobile is traded in on this year’s new extra-fancy model.

The effect of all this upon the load factors of the industry concerned is to cause it to run with a short spurt at peak production while getting out the new model or the latest style, and then idling or remaining completely shut down for the rest of the year. In men’s clothing, for example, with a relatively small variety of stabilized styles and an ample variety of materials and color combinations, clothing could be manufactured, if need be, for a year or even two years in advance, and thus completely even out the peaks and troughs resulting from seasonal demands for different kinds of clothing. Overcoats, for example, could be manufactured the year round with a high load factor, but at a rate just sufficient for the annual output to be equal to a single winter’s needs.

Unnecessary Activities. As yet little emphasis has been placed on the fact that by far the greater part of all employees are engaged in one kind or another of financial accounting or other similar socially unnecessary activities. Even in so industrial a unit as a flour mill it is common for the number of employees engaged in the purely business operations of the plant to be considerably greater than the number required to operate the flour mill. In our electric light and power systems the bulk of the employees are the office clerks, the meter readers and repair men. Only a small percentage of the total staff are required for the socially necessary industrial function of operating and maintaining the power system.

All this is aside from the unnecessary duplication that exists. One single store, for instance, could supply all the distribution services required by a population of 10,000, or so, with only a matter of a couple of dozen employees, whereas in actuality there were in 1929, 683,751 retail stores employing 3,081,000 people (including the proprietors) serving a population of 48,000,000 in all the cities of the United States of populations over 30,0001*. This means that in the cities of over 30,000 in the United States there was at that time one retail store employing on the average 41/2 people full time for every 70 members of the population, or one employee in a retail store for every 15.5 members of the population.

In 1930 there were over six million people in the United States engaged exclusively in trade. This is, of course, in addition to the employees already mentioned whose jobs are largely financial, rather than industrial. There were over four million clerical positions, consisting of bookkeepers, accountants, and the like in the United States in 1930.

The point of all this is that, with a re-design of our social mechanism along the lines indicated, there will be a much larger number of jobs which will cease to exist than of new jobs which will be created. This would not imply then, as it does now, that there would be unemployment. It merely signifies, on the one hand, that we are assured of an ample supply of human services for all possible contingencies while operating the mechanism at the highest output per capita ever achieved. It means, in addition that all this will be accomplished simultaneously with a shortening, rather than with a lengthening of the working day.

References:

- Reshaping Agriculture, Willcox

- ABC of Agrobiology, Willcox